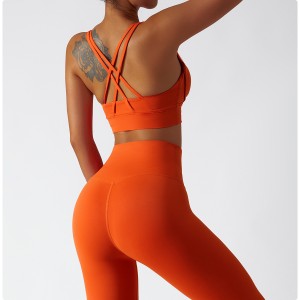

In the ever-evolving world of fashion, the demand for high-quality, custom activewear has surged, prompting manufacturers to refine their processes to meet consumer expectations. One of the most critical stages in this journey is the sample-making process, which serves as the foundation for creating bespoke activewear that not only meets aesthetic standards but also delivers on performance and comfort.

At the heart of custom activewear manufacturing lies the intricate art of pattern making. This process involves creating templates that dictate the shape and fit of the garments. Skilled pattern makers meticulously draft designs that consider various factors, including fabric stretch, body movement, and intended use. Whether it’s for yoga, running, or high-intensity workouts, each piece of activewear must be tailored to enhance the wearer’s experience.

The sample-making phase is where creativity meets functionality. Once the patterns are established, manufacturers produce initial samples to evaluate the design's practicality. This stage is crucial, as it allows designers and manufacturers to assess the fit, fabric behavior, and overall aesthetic of the activewear. Custom activewear manufacturers often utilize advanced technology, such as 3D modeling and digital prototyping, to streamline this process, ensuring that the final product aligns with the original vision.

Feedback from athletes and fitness enthusiasts plays a pivotal role in refining these samples. Custom activewear manufacturers often collaborate with professional athletes to test the garments in real-world conditions. This collaboration ensures that the final product not only looks good but also performs exceptionally well during rigorous activities. Adjustments are made based on this feedback, leading to a final sample that embodies both style and functionality.

Sustainability is another critical consideration in the custom activewear manufacturing process. As consumers become more environmentally conscious, manufacturers are increasingly sourcing eco-friendly materials and implementing sustainable practices in their production lines. The sample-making process is no exception; manufacturers are exploring innovative fabrics made from recycled materials and utilizing dyeing techniques that minimize water usage and chemical waste.

Moreover, the rise of e-commerce has transformed how custom activewear is marketed and sold. With the ability to reach a global audience, manufacturers are now able to offer personalized options that cater to individual preferences. This shift has led to an increased focus on the sample-making process, as brands strive to provide a seamless online shopping experience. Virtual fitting rooms and augmented reality tools are being integrated into the design process, allowing customers to visualize how the activewear will look and fit before making a purchase.

As the custom activewear market continues to grow, the importance of an efficient and innovative sample-making process cannot be overstated. It serves as the bridge between concept and reality, ensuring that each piece of activewear is not only unique but also functional and sustainable. Custom activewear manufacturers are at the forefront of this evolution, leveraging technology and consumer insights to create products that resonate with today’s health-conscious and style-savvy consumers.

In conclusion, the sample-making process is a vital component of custom activewear manufacturing, blending artistry with practicality. As manufacturers continue to refine their techniques and embrace sustainability, the future of activewear looks promising, offering consumers a diverse range of options that cater to their individual needs and preferences. With a commitment to quality and innovation, custom activewear manufacturers are poised to lead the industry into a new era of fashion that prioritizes both performance and style.

If you are interested in us, please contact us

Post time: Dec-18-2024